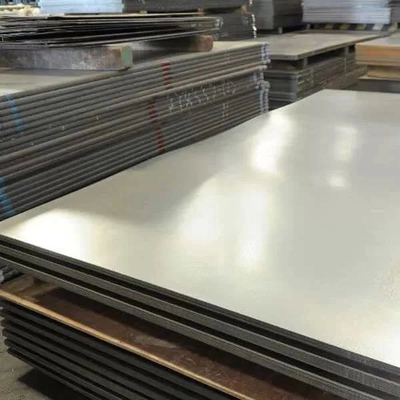

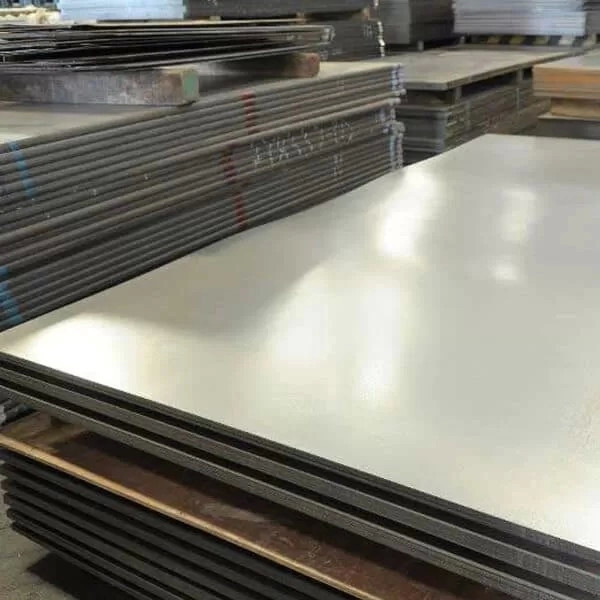

430 Stainless Steel Sheet with Low Nickel Content and Optional Molybdenum for Improved Durability and Oxidation Resistance

Product Details:

| Place of Origin: | shanxi,China |

| Brand Name: | ShanXi Taigang Stainless Steel Co., Ltd. |

| Certification: | CE |

| Model Number: | 430 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1ton |

|---|---|

| Price: | negotiate |

| Packaging Details: | According to customer needs |

| Delivery Time: | 8-14 days |

| Payment Terms: | T/T, Western Union |

| Supply Ability: | 300 TONS PER WEEK |

|

Detail Information |

|||

| Application: | Medical, Construction,nuclear Power, Hydropower | Length: | Customized |

|---|---|---|---|

| Name: | 430 Cold Rolled Stainless Steel Plate | Thickness: | 0.4-3mm |

| Width: | 1m | Steel Grade: | 430 |

| Surface Finish: | BA/2B/NO.1/NO.3/NO.4/8K/HL/2D/1D | Processing Service: | Bending, Welding, Decoiling, Punching, Cutting |

| Highlight: | 430 Stainless Steel Coil Sheet,Stainless Steel Coil Sheet 409,Cold Rolled Stainless Steel Sheet HL |

||

Product Description

430 Stainless Steel Sheet with Low Nickel Content and Optional Molybdenum for Improved Durability and Oxidation Resistance

Product Overview & Working Principle

The HL 430 Stainless Steel Coil Sheet, featuring a 409 cold-rolled mirror finish, is a premium-grade ferritic stainless steel known for its excellent thermal and mechanical properties. Manufactured through a cold rolling process, this coil sheet offers enhanced surface smoothness, superior strength, and high corrosion resistance. The cold rolling refines the grain structure, improving toughness and dimensional accuracy, making it ideal for precision applications. Its composition includes 16-18% chromium, low nickel content, and optional molybdenum, enhancing oxidation resistance and durability.

Applications

430 stainless steel coil sheets are widely used in diverse industries due to their versatility and durability:

-

Building Decoration: Ideal for architectural panels, ceiling tiles, and decorative trims thanks to its aesthetic mirror finish and corrosion resistance.

-

Fuel Burner Components: Withstands high temperatures and oxidation, making it perfect for burner parts and heat exchangers.

-

Household Appliances: Commonly used in manufacturing durable home appliances like refrigerators, ovens, washing machines, and microwave ovens.

-

Automotive and Bicycle Parts: Grades like 430LX with Ti or Nb additions provide improved welding and forming performance, suitable for bicycle flywheels and automotive components.

-

Fasteners & Machined Parts: The 430F grade, specially designed for enhanced machinability, is ideal for automatic lathe operations producing bolts, nuts, and screws.

Advantages

-

Excellent Corrosion Resistance: Chromium content between 16-18% forms a passive oxide layer, protecting against rust and chemical exposure.

-

Good Thermal Stability: Melting point at 1427°C ensures performance in high-temperature environments.

-

Superior Mechanical Strength: Yield strength ≥ 205 N/mm² and tensile strength ≥ 450 N/mm² make it robust for structural applications.

-

Cold Rolled Mirror Finish: Provides an attractive surface with smoothness and enhanced wear resistance, suitable for visible parts and architectural use.

-

Versatile Processing: Supports bending, welding, punching, and cutting with minimal deformation.

-

Cost-Effective: Compared to austenitic grades, 430 stainless steel offers high performance at a competitive price.

Specifications

| Parameter | Value |

|---|---|

| Composition | Cr: 16-18%, Ni ≤ 0.60%, Mn ≤ 1.00%, S ≤ 0.030%, P ≤ 0.040%, Mo: 2-3% (optional) |

| Thickness | 0.01 mm – 200 mm |

| Surface Finish | Cold Rolled, 2B, Mirror, Cross Hairline, NO.1, BA, NO.4, NO.8, Golden Mirror |

| Width | Customizable (1000, 1219, 1250, 1500, 1800 mm, or as required) |

| Mechanical Properties | Yield Strength ≥ 205 N/mm², Tensile Strength ≥ 450 N/mm², Hardness HV ≤ 200, HRB ≤ 88 |

| Melting Point | 1427 °C |

| Standards | ASTM, ISO 9001, API, CE, RoHS, BIS, SASO, PVOC, SONCAP, SABS, JIS |

Main Markets

Our HL 430 Stainless Steel Coil Sheet serves global markets including:

-

Construction and architectural firms

-

Home appliance manufacturers

-

Automotive and bicycle parts producers

-

Chemical and fuel burner equipment manufacturers

-

Industrial fastener and machining companies

Why Choose Us?

We ensure strict quality control, competitive pricing, and cutting-edge production technologies. Our team offers professional engineering support, smooth communication, and effective OEM & ODM services to meet your customized requirements. Available in stock with prompt delivery (8-14 days), we provide a reliable solution for your stainless steel needs.